BONLAB BLOG

Thoughts

&

Scientific Fiction

Warwick drives green growth with £13.6M EPSRC hub in plastics

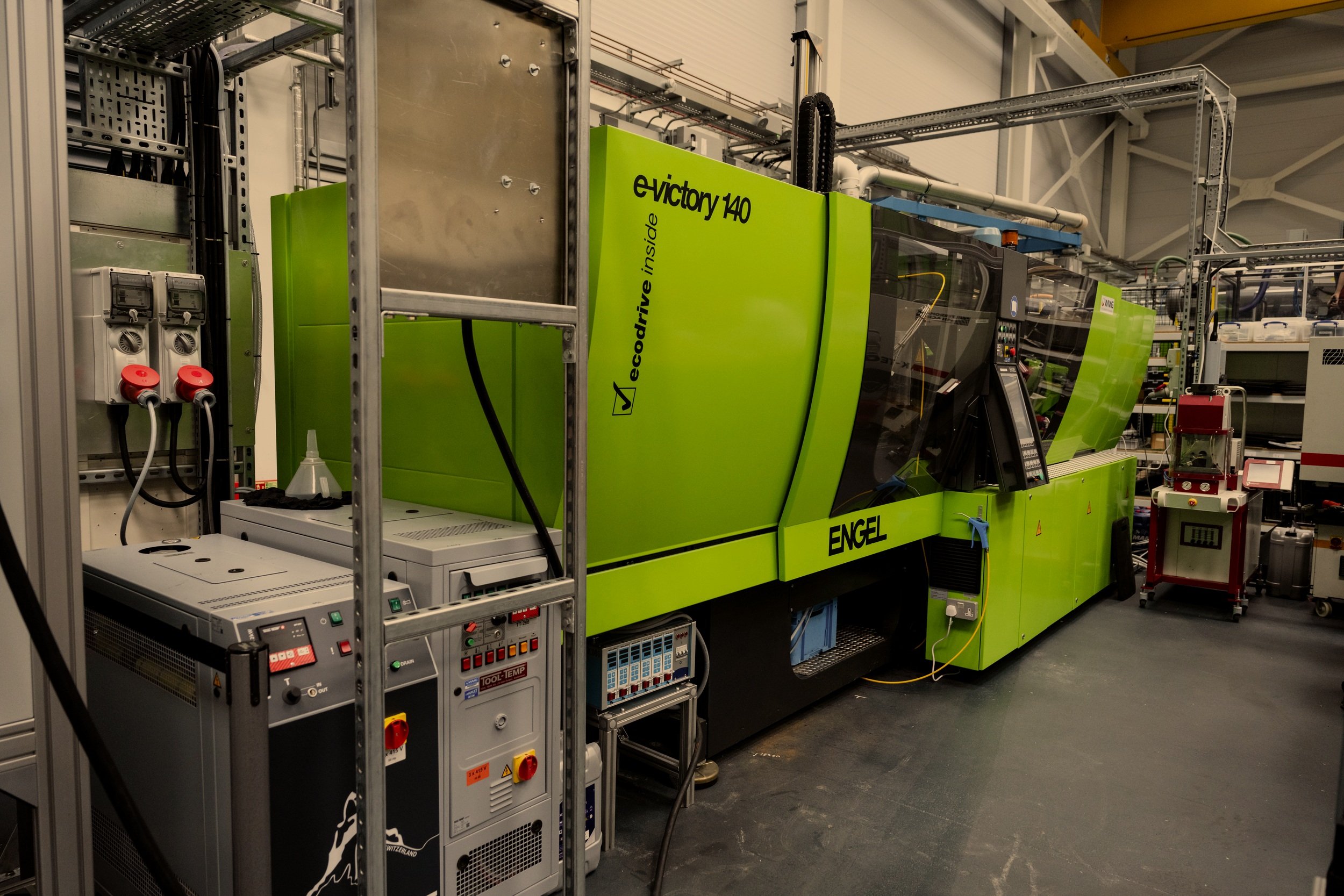

From developing greener materials and processes to growing more sustainable supply chains, a new £13.6 million research hub, funded by the Engineering and Physical Sciences Research Council (EPSRC), will help researchers at the University of Warwick tackle some of the UK’s biggest manufacturing challenges.

The new Manufacturing Research Hub in Sustainable Engineering Plastics (SEP) will be led by Professor of Polymer Processes, Ton Peijs, at WMG, and has Professor of Polymer and Colloid Chemical Engineering, Stefan Bon, at the Department of Chemistry as one of the co-investigators.

From developing greener materials and processes to growing more sustainable supply chains, a new £13.6 million research hub, funded by the Engineering and Physical Sciences Research Council (EPSRC), will help researchers at the University of Warwick tackle some of the UK’s biggest manufacturing challenges.

The new Manufacturing Research Hub in Sustainable Engineering Plastics (SEP) will be led by Professor of Polymer Processes, Ton Peijs, at WMG, and has Professor of Polymer and Colloid Chemical Engineering, Stefan Bon, at the Department of Chemistry as one of the co-investigators.

Researchers from Warwick will work, over the next seven years, alongside the University of Manchester and UCL to improve the way durable plastics – commonly used in cars, buildings, and electronics – are created, reused, and recycled. Researchers aim to reduce waste, support greener manufacturing practices, and advance the circular economy, with support from over 60 industry partners, including JLR, Polestar, Siemens, BEKO, Bellway, and Biffa, to turn research into real-world solutions.

By focusing on practical needs, the Hub will help move the UK toward a circular economy—where products are reused instead of thrown away. The work will support businesses in reducing waste and minimizing their environmental impact, while maintaining competitiveness. It will also strengthen local supply chains and help shape future policies that promote innovation and sustainability in the UK manufacturing sector.

Professor Ton Peijs, Project Lead, of the EPSRC Manufacturing Research Hub in Sustainable Engineering Plastics, said: “We’re incredibly proud to lead this vital initiative. Until now, most sustainability efforts in plastics have focused on single-use items and packaging. Yet engineering plastics - essential to modern life - present equally complex sustainability challenges that have, until now, largely been overlooked.

This Hub unites researchers, industry leaders, and policymakers to fundamentally rethink how engineering plastic parts are designed, reused, repaired and recycled. We’re focused on real-world impact: using greener materials, smarter manufacturing and recycling systems, and more sustainable supply chains.

This grant underscores the urgent need for innovation in this space, and we’re excited to drive meaningful, lasting change.”

Professor Stefan Bon, co-investigator, from the Department of Chemistry says: “We at Warwick, the University of Manchester, and UCL worked tremendously hard to get this initiative over the line. It is good to see that the UK government recognises the value of its polymer science and engineering capabilities. The next 7-8 years will be fantastic!”

The Hub is one of four, backed by a total of £44 million through the EPSRC the new Manufacturing Research Hubs for a Sustainable Future will bring together world-class researchers with over 180 industry and civic partners to drive practical, sustainable innovation across the UK.

Each hub will focus on a different critical area of manufacturing, including creating net-zero supply chains and resilient production systems, as well as transforming waste and reducing our reliance on fossil fuels.

Professor Charlotte Deane, Executive Chair of EPSRC, said: “These hubs will play a vital role in reshaping manufacturing to help the UK achieve green growth. By combining deep research expertise with real-world partnerships, they will develop the technologies, tools, and systems we need for clean, competitive, and resilient industries.”

For more info see UKRI: https://www.ukri.org/news/new-research-hubs-to-cut-carbon-and-reshape-uk-manufacturing/

Water-based nanocapsule dispersions for tuneable energy storage

Phase change materials, also known as PCMs, can capture, store, and release energy when they undergo a phase transition. One class of PCMs with relatively high latent energy storage capabilities are alkane-based waxes. These store energy upon melting and will release it again when they solidify through crystallization. To make use of this so-called latent heat is helpful for many applications, and indeed can be found, for example, in building insulation and temperature regulation materials. If, however, we would like to use this concept in a temperature-regulating fluid, we need to disperse the PCMs into a liquid, such as water, that in itself has a high heat capacity and thus the ability to store energy.

Phase change materials, also known as PCMs, can capture, store, and release energy when they undergo a phase transition. One class of PCMs with relatively high latent energy storage capabilities are alkane-based waxes. These store energy upon melting and will release it again when they solidify through crystallization. To make use of this so-called latent heat is helpful for many applications, and indeed can be found, for example, in building insulation and temperature regulation materials. If, however, we would like to use this concept in a temperature-regulating fluid, we need to disperse the PCMs into a liquid, such as water, that in itself has a high heat capacity and thus the ability to store energy.

Creating a dispersion of PCMs is a complex task that presents an intellectual challenge. If we were to emulsify molten wax using ordinary surfactants into droplets dispersed in water, a problem would arise upon cooling. When certain wax droplets crystallize, these will touch other droplets in their vicinity triggering crystal growth and fusion of the droplets. The emulsion is destabilized and, upon heating, will not return to its original state. This complexity underscores the urgent need for innovative solutions in the field of materials science.

The solution to this challenge is to encapsulate the wax. This involves surrounding the wax droplets with a protective shell that prevents fusion. However, a new problem arises when the capsules are large, such as in the micron length scale or upwards. In these cases, the capsules can still jam together and obstruct the flow of the liquid. To overcome this, we need to miniaturize the entire system and fabricate wax nanocapsules that remain colloidally stable throughout their application. This approach not only solves the problem but also allows us to blend nanocapsules containing different waxes, thereby tuning the energy storage characteristics.

Our paper recently published in the Royal Society of Chemistry journal Polymer Chemistry and entitled: “Phase change material nanocapsules for latent function thermal fluids with tuneable thermal energy storage profiles” does exactly that.

We prepared mini-emulsions, which are stable tiny droplets of various methacrylates in the presence of trimethylolpropane trimethacrylate (TMA) as a crosslinker, and n-hexadecane (HD), n-octadecane (OCT), and n-docosane (DOC) as PCM. One important aspect was to use an ω-unsaturated poly(n-butyl methacrylate-b-[(methacrylic acid)-co-(methyl methacrylate)]) macromonomer as a reactive macromolecular emulsifier, to secure colloidal stability of our nanocapsule systems. The performance of a thermal fluid of DOC nanocapsules was tested against water, with promising results. As a tunability concept, crosslinked poly(methyl methacrylate) nanocapsules of n-octadecane (OCT) and n-docosane (DOC) were blended as a tuneable latent function thermal fluid.

You can read the paper here:

Water-Based Acrylic Latexes are excellent Pressure Sensitive Adhesives when Branched

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

Water-based pressure sensitive adhesives (PSAs) are typically made by emulsion polymerization using a low glass transition temperature base monomer, such as n-butyl acrylate or 2-ethyl hexylacrylate, together with a range of functional comonomers. Typically these include a high glass transition temperature comonomer, such as styrene or methyl methacrylate and monomers that can promote wetting and undergo secondary interactions such as (meth)acrylic acid.

A golden rule for good adhesive performance is that the polymer latex particles must contain a certain fraction of gel, that is, cross-linked material. This typically is 50-70%. This gel content optimizes the balance between tack and cohesive forces within the adhesive.

Schematic of the branched polymer chain architecture approach to deliver good performance in pressure sensitive adhesives (PSAs).

In our paper, led by PhD researcher Emily Brogden and published in the RSC journal Polymer Chemistry, we challenged this view. Prof. dr. ir. Stefan Bon says: “We designed a range of polymer latexes with low gel content. To balance the adhesive forces, we introduced a branched polymer chain architecture instead. We show that excellent water-based acrylic PSAs can be made using this approach.”

Moreover, the chemical composition of our PSA was designed with sustainability in mind. The base monomer selected was the bio-based 2-octyl acrylate, the high Tg component bio-based 2-isobornyl acrylate. The other monomers and chain transfer agent show promise to be or become fully bio-based.

The paper entitled “Water-Based Polymer Colloids with a Branched Chain Architecture as Low-Gel Pressure-Sensitive Adhesives” has gold open access and can be read here: