BONLAB BLOG

Thoughts

&

Scientific Fiction

£2.3M boost to revolutionize optical and mechanical metamaterials

Researchers from the University of Cambridge and the University of Warwick have secured £2.3M in UKRI funding to create materials with radically new optical and mechanical properties, that can be produced at scale and low cost.

Researchers from the University of Cambridge and the University of Warwick have secured £2.3M in UKRI funding to create materials with radically new optical and mechanical properties, that can be produced at scale and low cost.

The new funding will allow the multi-disciplinary team to push the boundaries of what is possible with metamaterials.

Optical metamaterials are special materials designed to control light waves in ways that natural materials cannot. These materials can bend, absorb, or reflect light in unusual ways, making them useful for a variety of applications.

With the Reconfigurable Nano-Opto-Mechanical Metamaterials (RENOMM) project, researchers aim to create metamaterials using nanoscale building blocks that can be self-assembled and disassembled for reuse at the end of their life.

This involves developing a new synthesis and scalable processing platform for 3D sub-micron sustainable materials. These materials will combine mechanical, optical, optomechanical, and other functionalities, opening up new possibilities for metamaterial applications. These include new sensors for health biomarkers, thermal switching films, or mechanical information processing.

The project seeks to disrupt existing approaches and capitalise on the UK’s strengths in 3D self-assembly. The goal is to develop 3D metamaterials (3DMMs) that can be produced at scale and low cost, enabling a wide range of new applications.

One of the key challenges for RENOMM will be to incorporate, for the first time, both mechanical bistability and nonlinearity into these new materials. It will also tackle fundamental questions about how to assemble and disassemble these structures at the nanoscale, and seek to unlock the new properties that emerge from this process.

“Mechanical metamaterials often break our intuition about what is possible with mechanics, but have mostly been at explored using large, centimetre-scale patterns. Making these patterns at the nanoscale is an exciting new frontier,“ according to Anton Souslov, Associate Professor in the Cavendish Laboratory and one of the Co-Investigators of RENOMM.

The project will involve collaboration between experts in physics, chemistry, and engineering, going beyond previous work that has focused only on macroscale mechanical systems and nanoscale 2D microfabricated optical devices.

All 3DMMs will be evaluated based on their materials’ sustainability and compatibility with low-emission, cost-efficient, and ideally circular manufacturing processes.

The core of the project is a close collaboration between researchers at the Cavendish Laboratory – (Professor Jeremy Baumberg, Professor Ulrich Keyser and Dr Anton Souslov – as well as the Department of Engineering with Professor Michael de Volder) and researchers at the University of Warwick’s Chemistry Department from the team of prof. dr. ir. Stefan Bon.

Prof. dr. ir. Stefan Bon, lead scientist from the University of Warwick, says: “The RENOMM project is a fantastic initiative that will bring together the forefronts of supracolloidal science, roll-to-roll processing, and bespoke bottom-up metamaterials design to mass-produce submicron-scale products with fascinating optical and mechanical 3DMMs features.”

RENOMM is an initiative sparking from MetaHUB, a pioneering new research collective, designed to spearhead the UK’s world leading, cutting-edge 3D nanoscale metamaterials science.

Original source URL: https://www.phy.cam.ac.uk/news/cambridge-team-receives-major-boost-to-revolutionise-optical-metamaterials/

Warwick drives green growth with £13.6M EPSRC hub in plastics

From developing greener materials and processes to growing more sustainable supply chains, a new £13.6 million research hub, funded by the Engineering and Physical Sciences Research Council (EPSRC), will help researchers at the University of Warwick tackle some of the UK’s biggest manufacturing challenges.

The new Manufacturing Research Hub in Sustainable Engineering Plastics (SEP) will be led by Professor of Polymer Processes, Ton Peijs, at WMG, and has Professor of Polymer and Colloid Chemical Engineering, Stefan Bon, at the Department of Chemistry as one of the co-investigators.

From developing greener materials and processes to growing more sustainable supply chains, a new £13.6 million research hub, funded by the Engineering and Physical Sciences Research Council (EPSRC), will help researchers at the University of Warwick tackle some of the UK’s biggest manufacturing challenges.

The new Manufacturing Research Hub in Sustainable Engineering Plastics (SEP) will be led by Professor of Polymer Processes, Ton Peijs, at WMG, and has Professor of Polymer and Colloid Chemical Engineering, Stefan Bon, at the Department of Chemistry as one of the co-investigators.

Researchers from Warwick will work, over the next seven years, alongside the University of Manchester and UCL to improve the way durable plastics – commonly used in cars, buildings, and electronics – are created, reused, and recycled. Researchers aim to reduce waste, support greener manufacturing practices, and advance the circular economy, with support from over 60 industry partners, including JLR, Polestar, Siemens, BEKO, Bellway, and Biffa, to turn research into real-world solutions.

By focusing on practical needs, the Hub will help move the UK toward a circular economy—where products are reused instead of thrown away. The work will support businesses in reducing waste and minimizing their environmental impact, while maintaining competitiveness. It will also strengthen local supply chains and help shape future policies that promote innovation and sustainability in the UK manufacturing sector.

Professor Ton Peijs, Project Lead, of the EPSRC Manufacturing Research Hub in Sustainable Engineering Plastics, said: “We’re incredibly proud to lead this vital initiative. Until now, most sustainability efforts in plastics have focused on single-use items and packaging. Yet engineering plastics - essential to modern life - present equally complex sustainability challenges that have, until now, largely been overlooked.

This Hub unites researchers, industry leaders, and policymakers to fundamentally rethink how engineering plastic parts are designed, reused, repaired and recycled. We’re focused on real-world impact: using greener materials, smarter manufacturing and recycling systems, and more sustainable supply chains.

This grant underscores the urgent need for innovation in this space, and we’re excited to drive meaningful, lasting change.”

Professor Stefan Bon, co-investigator, from the Department of Chemistry says: “We at Warwick, the University of Manchester, and UCL worked tremendously hard to get this initiative over the line. It is good to see that the UK government recognises the value of its polymer science and engineering capabilities. The next 7-8 years will be fantastic!”

The Hub is one of four, backed by a total of £44 million through the EPSRC the new Manufacturing Research Hubs for a Sustainable Future will bring together world-class researchers with over 180 industry and civic partners to drive practical, sustainable innovation across the UK.

Each hub will focus on a different critical area of manufacturing, including creating net-zero supply chains and resilient production systems, as well as transforming waste and reducing our reliance on fossil fuels.

Professor Charlotte Deane, Executive Chair of EPSRC, said: “These hubs will play a vital role in reshaping manufacturing to help the UK achieve green growth. By combining deep research expertise with real-world partnerships, they will develop the technologies, tools, and systems we need for clean, competitive, and resilient industries.”

For more info see UKRI: https://www.ukri.org/news/new-research-hubs-to-cut-carbon-and-reshape-uk-manufacturing/

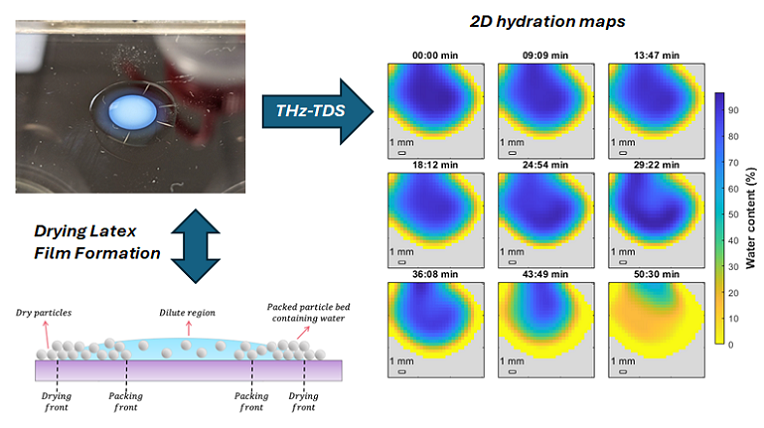

Visualizing the drying and film formation of polymer latexes

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

Polymer latex particles, typically 50-600 nm in diameter, are used in many applications, such as paper manufacturing, water-based adhesives, printing, and coatings. Commonly, a water-based formulation that contains these polymer colloids is used, often together with other components, such as pigments for opacity and color, fillers, and rheology modifiers. Each of the polymer latex particles consists of many individual polymer chains. These water-based dispersions are applied onto a substrate as a droplet or a film, after which these systems are dried. Upon evaporation of water, the individual components will pack closely. When little water remains in between, a so-called capillary under-pressure facilitates tight packing, and if the polymer latex particles are soft, it deforms them. The last stage of the film formation process is when polymer chains from one latex particle now diffuse into a neighboring latex particle and the other way around. This process ensures that the dried film has good adhesive and mechanical properties.

Visualizing this drying and film formation process in real time would greatly help in understanding how the properties of a dried film come about. In our paper, published in the American Chemical Society’s journal Langmuir, we used TeraHertz Time-Domain Spectroscopy (THz-TDS) to map the water content spatially in real-time during the drying process.

The use of TeraHertz Time-Domain Spectroscopy (THz-TDS) as a tool to visualize the water content in a drying polymer dispersion in real-time.

Emily Brodgen, a final year PhD researcher from BonLab, teamed up with Gonçalo Costa, a PhD researcher in the Department of Physics at the University of Warwick, working with the team of prof. Emma Pickwell-MacPherson, and together they studied the potentials THz-TDS could bring.

Prof. dr. ir. Stefan Bon says: “It is great to see this collaborative work. We believe that there are opportunities for THz-TDS to be used as an analytical tool in the field of water-based polymer dispersions, particularly how droplets or films dry after they have been deposited onto a surface. As you can read in the paper, which we very much see as a positioning study, there are great opportunities out there to refine the technique. We hope others are as enthusiastic as we are so that THz-TDS can be adopted wider as a measurement tool.”

The paper is freely available to all from ACS Langmuir and can be found here:

https://doi.org/10.1021/acs.langmuir.4c03103

For more information, please get in touch with prof. dr. ir. Stefan A. F. Bon directly.